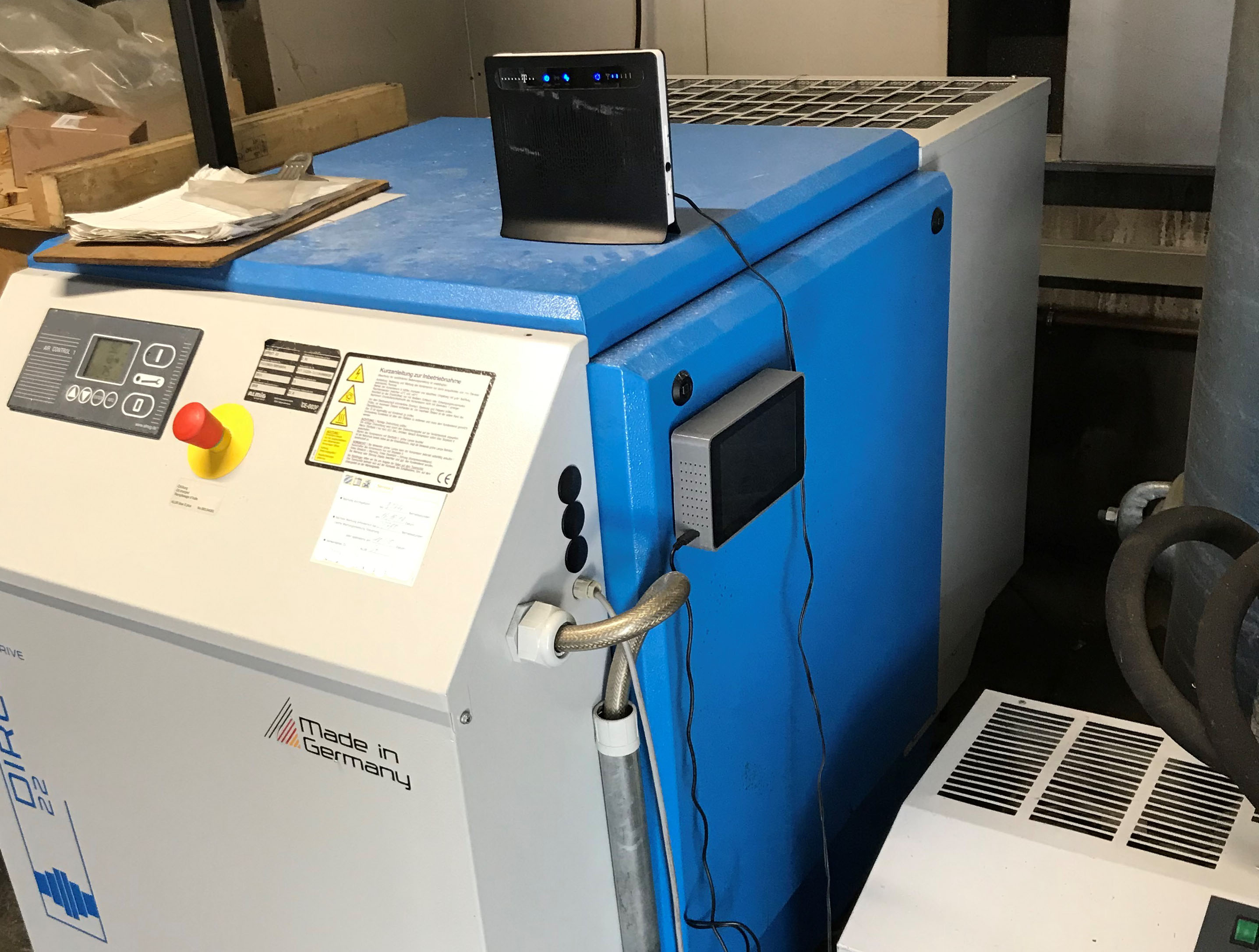

This is a central unit for cooling, filtering and conveying the cooling water, which ensures the removal of waste heat from all production machines in operation. Furthermore, the unit also serves to control specific process temperatures, which have a great influence on the quality of the products.

If the process temperature no longer corresponds to the prescribed process parameters, this very often leads to poor product quality and a high reject rate.

Problem: Failure affects the quality of the products and thus increases the reject rate

With insufficient cooling, certain machines can no longer be operated. The result: reduced production.

The industrial cooling is located in a separate room. A failure is often detected late. The maintenance intervals are periodic.

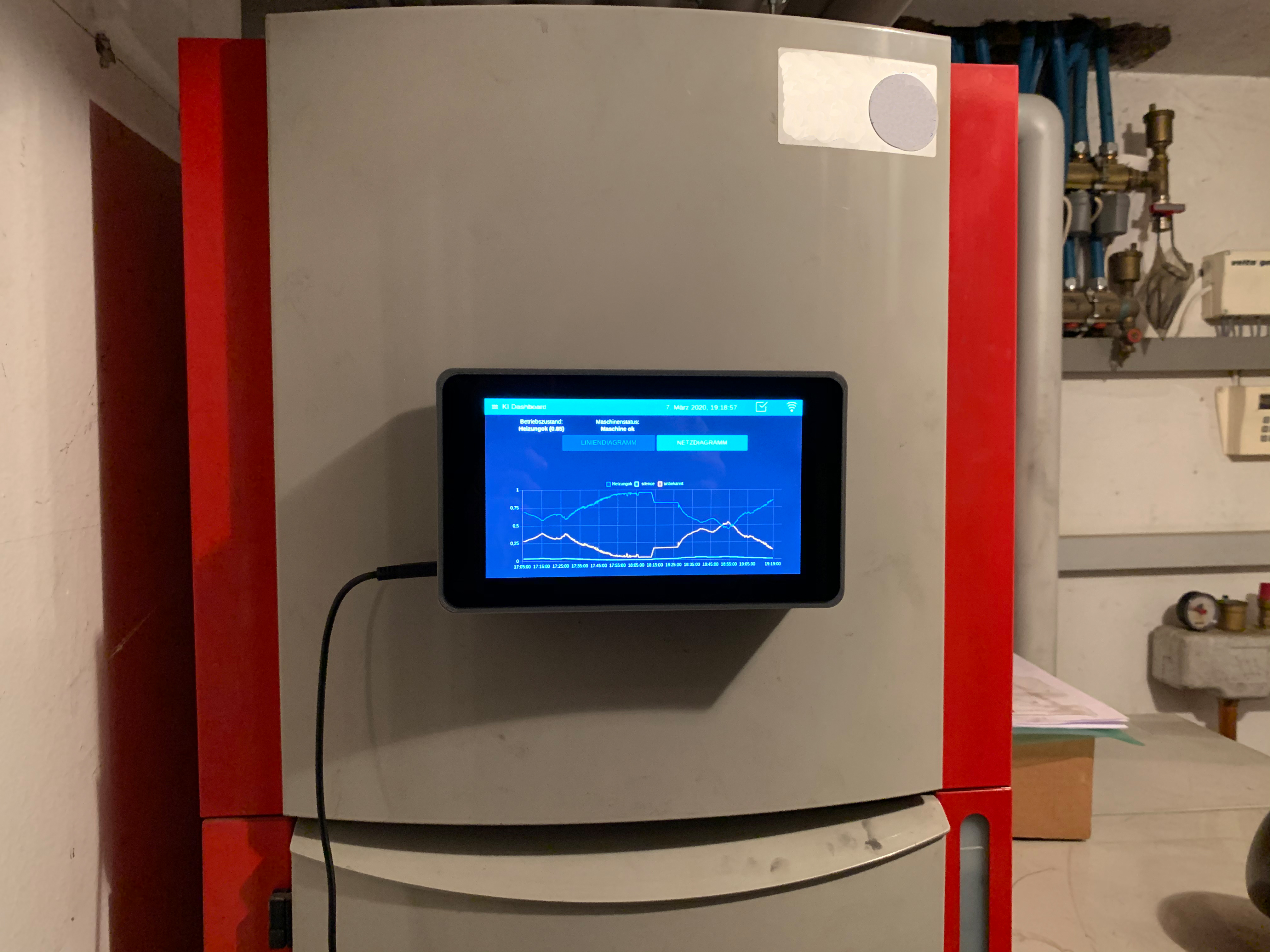

What are the advantages of using the Master Melody®?

“ Monitoring: Early detection of a failure is of central importance. In this way, a reduction in quality and a loss of production can be prevented. The alarm system gives a timely warning of an impending failure.”

“Predictive Maintenance: Maintenance work can be carried out at the optimum time and in a targeted manner to minimise the impact on production.”